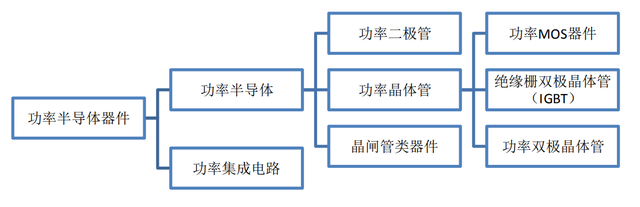

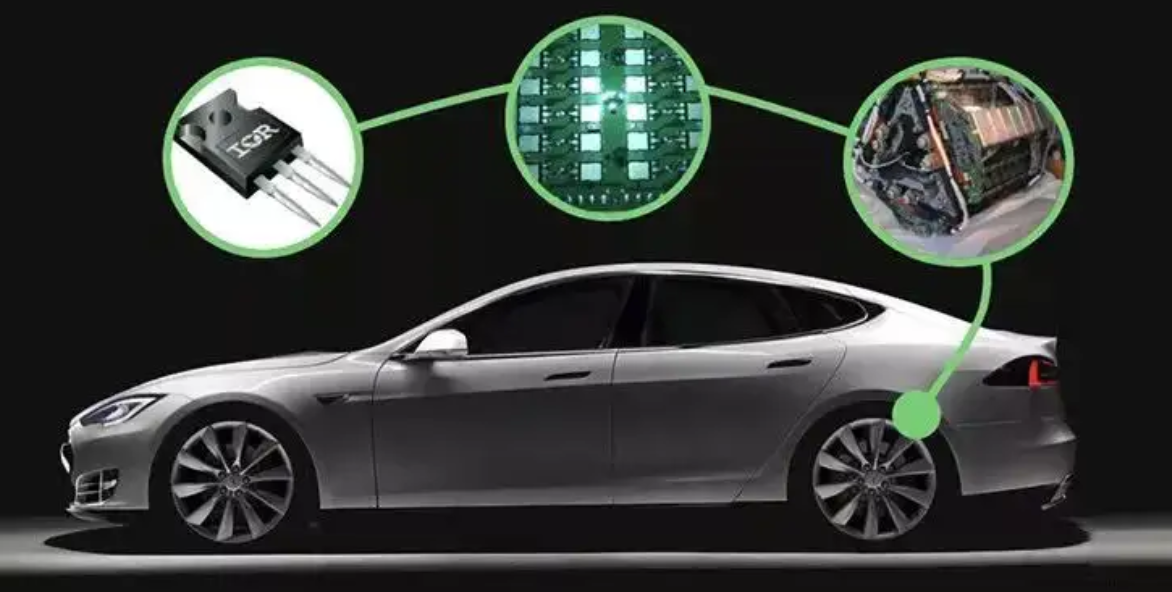

" As a national strategic emerging industry, IGBT is widely used in rail transit, smart grid, industrial energy conservation, electric vehicles and new energy equipment. Today, Jingtai will help you dismantle the current situation and investment trend of IGBT. |What is IGBT? IGBT (InsulatedGateBipolarTransistor) is a power semiconductor device. Its Chinese name is "Insulated Gate Bipolar Transistor". It is composed of BJT (Bipolar Junction Transistor) and MOSFET (Insulated Gate Field Effect Transistor). As the core power device for energy conversion and power control, IGBT is known as the "CPU" in the power semiconductor industry. In the context of "carbon peaking" and "carbon neutrality", the large-scale application of renewable energy such as solar energy, wind energy, thermal energy, and biomass energy has become an inevitable trend in the development of world energy. Among many power generation technologies, solar photovoltaic power generation is one of the important power generation methods in the concept of green environmental protection, and photovoltaic inverters are the core equipment of solar photovoltaic power generation. The performance of photovoltaic inverters can affect the stability and power generation of the entire photovoltaic system. Efficiency and service life. As the core component of photovoltaic inverters, IGBT not only occupies a very important position in power semiconductors, but also is the core device in new energy vehicles, photovoltaics, wind power, and energy storage inverters. With the continuous growth of photovoltaic installed capacity, the market demand for IGBTs has also risen rapidly. |Application scenarios of IGBTs IGBTs are widely used. Generally, low-voltage IGBTs are often used in variable frequency white goods, new energy vehicle parts and other fields; medium-voltage IGBTs are often used in industrial control, new energy vehicles and other fields; high-voltage IGBTs are often used in rail transit, power grids and other fields. From the perspective of application proportion, new energy vehicles account for 31% in the domestic market, which is the largest application field . Industrial control accounts for 28%, consumer electronics accounts for 20%, and new energy power generation accounts for 11%. The main function of IGBT used in automobiles is to convert the DC power of the high-voltage battery into the AC power to drive the three-phase motor in the inverter. The main inverter is responsible for controlling the motor. The maximum travel of the vehicle is directly related to the efficiency of the main inverter. To put it simply, IGBT has the ability of AC-DC conversion and frequency conversion. Through pulse width modulation, the IGBT can easily change the frequency of the AC power delivered to the motor, thereby precisely changing the motor speed and controlling the speed of the vehicle. And determine the vehicle's maximum output power (top speed), torque (acceleration, climbing ability). IGBT is the core electronic device of electric vehicle inverter, accounting for 52% of the semiconductor value of electric vehicle power system and 8-9% of the total vehicle cost. In addition, the cost of IGBT accounts for 15-18% of the DC fast charging piles supporting electric vehicles. The value of power devices of new energy vehicles is 20 times that of traditional vehicles, and many modules can achieve higher power and faster acceleration. Star Semiconductor and Times Electric are the manufacturers with the fastest domestic breakthroughs. It is difficult for pure designers in the field of new energy vehicles to enter. OEMs have very high requirements on the consistency, reliability and life of in-vehicle applications, including fixed output and production lines. IDM is the mainstream in the industry, and international manufacturers such as Infineon , ABB, Mitsubishi, Fuji Electric, etc. are all of this model. Therefore, the prosperity of the domestic IGBT market, new energy vehicles, industrial control, consumption and new energy power generation industries is the most worthy of our attention. Especially in the demand for new energy vehicles, photovoltaics and wind power, the proportion will continue to rise in the future. With the continuous development of my country's new energy field, it will be the largest downstream market in the future. From the perspective of new energy vehicles, the field of new energy vehicles is currently the largest incremental market for IGBTs. IGBTs are mainly used in electric drive systems, vehicle air conditioning systems and charging piles in electric vehicles. Among them, the IGBT module in the electric drive system is the most valuable part. |From the perspective of this year, which field of IGBT is growing faster? From the domestic production capacity and demand, it is expected that the growth rate of IGBTs of new energy vehicles will greatly exceed that of photovoltaics. The market for new energy vehicles, both overseas and domestic, is very strong, from 3.5 million last year to more than 5 million this year, but from the perspective of demand, 500w or even 550w is no problem, and the growth rate exceeds 50%. If the photovoltaic module is excluded, only the single tube is considered, and domestic manufacturers will accelerate the replacement of this part. In general, the supply and demand of IGBTs will remain tight throughout 2022 and are expected to continue into the second half of 2023. Therefore, for investment, you can focus on two types of listed companies: The first is IDM manufacturers with their own fabs, which can pay attention to Silan Micro, Times Electric, China Resources Micro, Wingtech and so on. The second is the excellent design companies with deep cooperation with domestic foundries that are actively expanding production, such as Star Semiconductor, New Clean Energy, Yangjie Technology, Macro Micro Technology, Dongwei Semiconductor, etc. The article is an information point compiled by Jingtai and does not constitute investment advice. Please read it carefully.