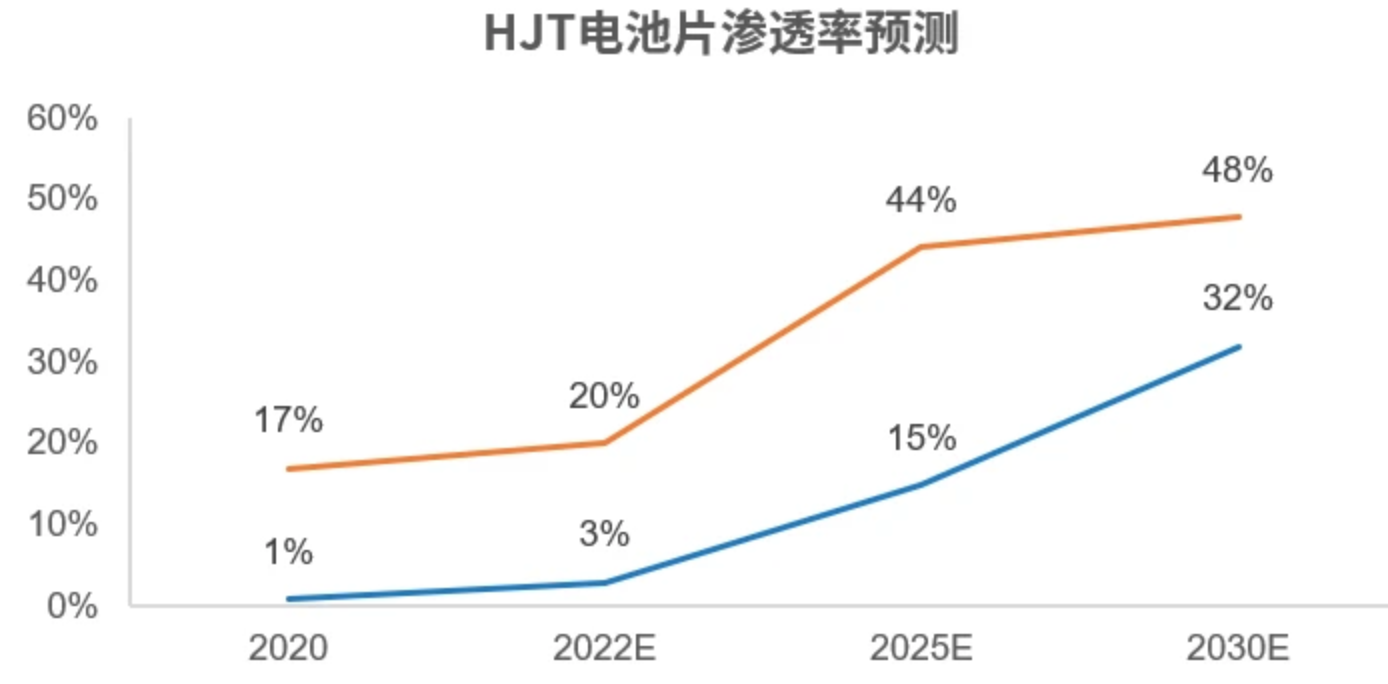

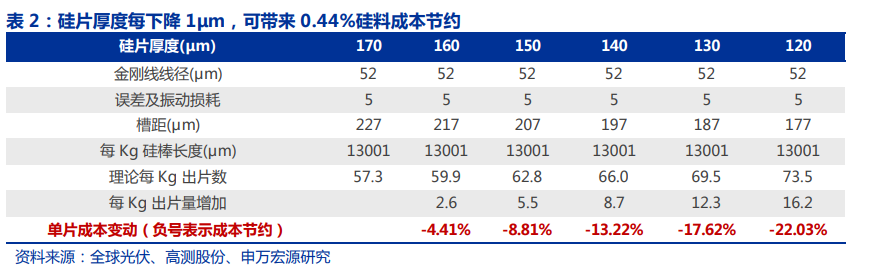

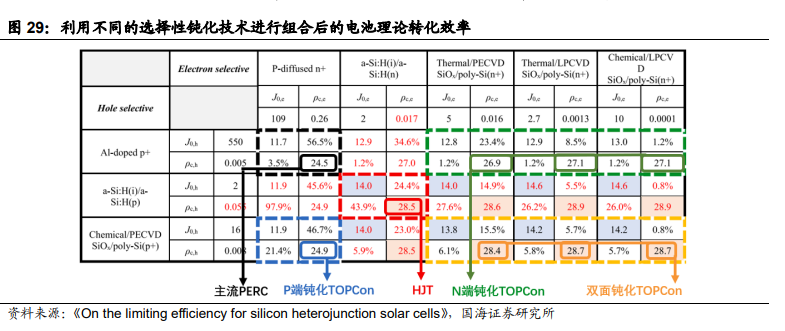

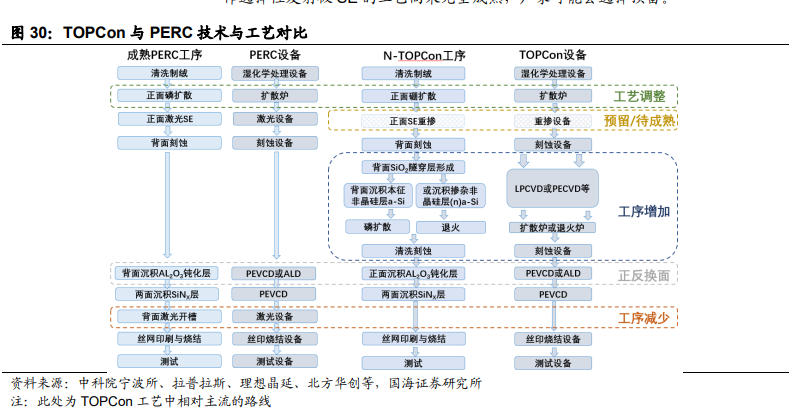

In the context of dual carbon, the photovoltaic industry has developed rapidly, and photovoltaic cell technology has gradually entered a critical period of new and old iterations. At present, the mainstream N-type battery technologies on the market include TOPCon, HJT and IBC batteries. The ultimate efficiency of TOPCon is 27.5%, and the transformation cost is low. It has become the development direction of battery technology in the next 2-3 years; HJT has high mass production efficiency and a clear cost reduction route, and may become a longer-term mainstream battery technology. |What is HJT? HJT battery: that is, amorphous silicon thin film heterojunction battery. It is a heterojunction composed of two different semiconductor materials. Crystalline silicon heterojunction solar cell (HJT) is a thin film of amorphous silicon deposited on crystalline silicon. It combines the advantages of crystalline silicon cells and thin film cells, and has the advantages of high conversion efficiency, low process temperature, high stability, low decay rate, With the advantages of double-sided power generation, the technology is subversive. The current difficulties in the industrialization of HJT batteries are mainly due to the high initial equipment investment cost and raw material cost, which are 3 times and 2 times that of PERC batteries respectively. Driven by this, the unit production cost of HJT cells is expected to drop to 0.52 yuan/W or even lower within 2~3 years, realizing partial replacement of PERC cells. By then, the penetration rate of HJT cells will rapidly increase from the current 3% to 10%. %above. It is expected that the penetration rate of HJT cells will increase to 15% and 32% by 2025 and 2030, respectively. |Why are you optimistic about photovoltaic HJT? The essence of battery technology iteration is that cost reduction and efficiency improvement, high efficiency and low cost are the direction of development. The main advantages are reflected in five aspects. One is the low temperature process, the processing temperature is lower than 200℃-250℃, on the one hand, it can reduce the energy consumption, and more importantly, it can greatly reduce the thermal damage of the silicon wafer, which is conducive to the thinning of the silicon wafer, thereby reducing the cost. Second, there is no PID effect. HJT uses N-type substrate silicon wafers, doped with phosphorus, and does not have the problems of boron-oxygen composite and boron-iron composite that P-type silicon wafers face. The third is low temperature coefficient. HJT has good temperature characteristics in both high temperature and low temperature environments. The fourth is the double-sided symmetrical structure, which can improve the power generation revenue of the battery; the fifth is the high open circuit voltage, the intrinsic film can effectively passivate the interface defects of crystalline silicon and doped amorphous silicon, and the open circuit voltage is higher than that of conventional batteries. Several battery comparisons: 1) PERC: The process flow of PERC cells is relatively simple and the equipment is mature. In the past two years, some efficiency improvement processes have been standard, such as laser SE, alkali polishing, optical injection/electric injection, etc. The PERC technology is mainly based on the deposition of the passivation layer on the backside and laser grooving. On this basis, the front-side SE laser and optical injection/electrical injection annealing and other processes are added when the process is improved and optimized. 2) TOPCon: First, a 1-2nm tunnel oxide layer is prepared on the back of the cell, and then a layer of doped polysilicon is deposited. The two together form a passivation contact structure, providing good interface passivation for the back of the silicon wafer. 3) HJT: Taking N-type single crystal silicon (C-Si) as the substrate light absorption area, after texturing and cleaning, an intrinsic amorphous silicon film with a thickness of 5-10nm (ia-Si:H ) and doped P-type amorphous silicon (Pa-Si:H), and the silicon substrate forms a pn heterojunction. The back surface of the silicon wafer is formed by depositing ia-Si:H and doped N-type amorphous silicon (na-Si:H) with a thickness of 5-10nm. ), and finally formed metal-based electrodes on the top layers on both sides by screen printing, which is a typical structure of heterojunction cells. 4) IBC: a solar cell in which both the p+ doped region and the n+ doped region are placed on the back of the battery (non-light-receiving surface), and the light-receiving surface of the IBC battery is not blocked by any metal electrodes, thereby effectively increasing the short-circuit current of the battery and making the battery Energy conversion efficiency is improved. Comparison of the highest laboratory efficiency of photoelectric conversion: PERC is 24%; TOPCon is 26%, which is a small area laboratory record of 4 cm in Germany, and the highest commercialization efficiency of JinkoSolar is 25.4% in a large area; HJT is LONGi Green Energy The latest data from the M6 laboratory reaches 26.5%, while the theoretical efficiency of HJT+perovskite tandem cells can reach 43%. At present, the average efficiency of mass-produced microcrystalline HJT is 24.95%, and the yield rate is 96.4%, which has obvious advantages in efficiency improvement compared with other batteries. The east wind has arrived! The economic inflection point of HJT, the industrialization has accelerated. |Intensive layout of industrial chain In view of the characteristics and market prospects of HJT batteries, many companies in the industry chain have deployed related products. In terms of equipment manufacturers, Baoxin Technology will invest in R&D and trial production of HJT texturing cleaning machines and electroplating equipment in 2021. The related equipment is in the process of trial production and has obtained intentional orders. Maiwei expects that the overall market order scale of HJT will be 20-30GW in 2022 , and plans to invest 2.312 billion yuan for the industrialization project of heterojunction solar cell equipment. In terms of battery cells, based on the research and development results of the 400MWHJT test built in 2019 , Tongwei Co. , Ltd. will add a 1GWHJT pilot line for production in 2021 , and start the TOPCon mass production pilot test based on 210 size ; in April 2022 , Tongwei HJT products The conversion efficiency exceeds 25% . JA Solar has invested 300 million yuan in research on new metallization process development, new passivation film development, and new transparent conductive film development, and is building a pilot test line for the research and development of heterojunction cells. The pilot test line will be launched in 2022 . put into production in May . At the beginning of 2022 , the 250MW heterojunction battery project of Canadian Academy of Sciences Jiaxing Research Institute is under construction. King Kong Glass has invested in the construction of a 1.2GW large-scale half-cell ultra-high-efficiency heterojunction solar cell and module project. In May 2022 , the related production lines will be in the ramp-up stage, and the average conversion efficiency of microcrystalline HJT cells will reach 24.95% , with the highest conversion efficiency of the cell. It has reached 25.2% , and the mass production power of heterojunction modules has steadily reached more than 700W . Some customers have delivered heterojunction cell sales orders. Shuangliang Silicon Materials ( Baotou ) Co., Ltd. recently signed a frame supply contract for heterojunction-specific monocrystalline ingots with Anhui Huasheng New Materials Co., Ltd. , agreeing that the buyer will purchase 7,800 tons of monocrystalline ingots from the seller from 2022 to 2025. It is estimated that The total sales amount in 2022-2025 is 3.024 billion yuan. LONGi Green Energy recently announced that the company's M6 full-size cell has a photoelectric conversion efficiency of 26.50% , further expanding its lead in the efficiency of heterojunction cells. It is expected that the production cost per W of HJT cells will be equal to that of PERC by the end of 2022, and the industry-wide expansion will begin in 2023, and major manufacturers will begin to expand production on a large scale. In the medium and long term, HJT battery technology is expected to stand out among many cell technologies in the future, and become the mainstream technology in the industry within a certain period of time .