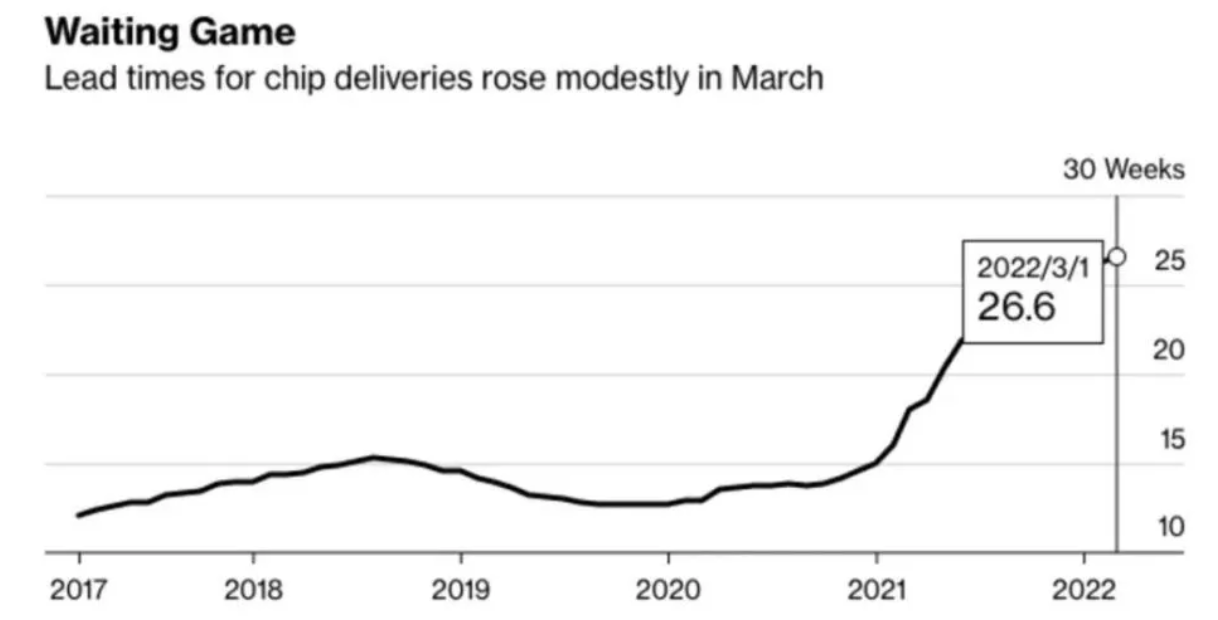

This unprecedented global chip shortage is becoming an important factor restricting the development of the global economy. The two-year-old "core shortage" has not yet eased, and it is even more severe. The skyrocketing chip prices caused by it are astounding. When will this long-lasting lack of cores be relieved?

▎What is the real reason for the shortage of chips?

1. In a force majeure epidemic, we must stand up and take the blame

Chip supply has been hit mainly in two ways:

First of all, from the fourth quarter of 2020 to the first quarter of 2021, the foundry capacity will be insufficient, the upstream wafer capacity cannot keep up with the rapid increase in demand, the supply and demand ends are unbalanced, and the wafer production expansion cycle is affected by the delivery of semiconductor equipment and factories. Assuming the influence of factors such as cycles, the phenomenon of chip shortages has continued.

The new crown epidemic has caused low operating rates, limited production capacity, and the outbreak of terminal application demand and dealers hoarding and speculating on prices, further exacerbating supply shortages.

Then in the third quarter of last year, the epidemic in many countries repeated, and the international situation changed, which led to a slowdown in chip shipments, and the "lack of cores" added to the haze.

In addition, the repeated outbreak of the epidemic has also caused the shutdown of chip manufacturing plants in Indonesia and Europe, and the deterioration of the international situation has caused a certain impact on semiconductor production capacity.

Of course, including China. Due to the severe epidemic situation in Shenzhen, Shanghai and Kunshan, Suzhou, chip semiconductor companies are facing important challenges.

2. Insufficient supply, slow expansion of chip manufacturing plants

Since the current global core shortage problem has not been effectively alleviated, major semiconductor manufacturers such as Intel and TSMC plan to expand production, hoping to grab market share and meet market demand. However, their expansion plan may not be completed as scheduled because the equipment cannot be delivered.

On March 21 this year, the British "Financial Times" reported that Peter Wennink, CEO of lithography giant ASML (Asmail), said recently that the multi-billion-dollar expansion plans of chip manufacturers will Constrained by shortages of critical equipment over the next two years, this shortage will make it difficult for the supply chain to improve production efficiency.

According to foreign media reports, major semiconductor equipment manufacturers such as KLA, LamResearch, and ASML have notified customers that due to the shortage of parts such as lenses, microcontrollers, engineering plastics and electronic modules , some key machines have to wait up to 18 months for delivery, while equipment for manufacturing substrates (even up to 30 months of delivery.

The lack of equipment supplies has created a sense of crisis for chipmakers. Intel CEO Henry Kissinger said equipment shortages have challenged the company's expansion plans, and Intel has sent its own manufacturing experts to the company to help speed up production. He stressed that the company still has time to solve the problem, and it will take two years to expand the chip factory.

▎When will the chip shortage crisis ease?

The media believes that the chip shortage will continue until 2022; Kissinger pointed out that it will take "several years" to ease; ASML said that the industry agreed that the chip shortage may last for two years; industry analysts also made such a prediction, saying, Chip shortages will continue until 2023.

As some companies increase their upstream prices to add wafer foundry capacity in the first quarter of 2021. Therefore, according to the changes in the historical semiconductor supply cycle, and when the epidemic is effectively controlled, he believes that it is expected that around 2022, the chip production cycle will decline, supply will rise, prices will fall, and the supply and demand structure will be significantly improved.

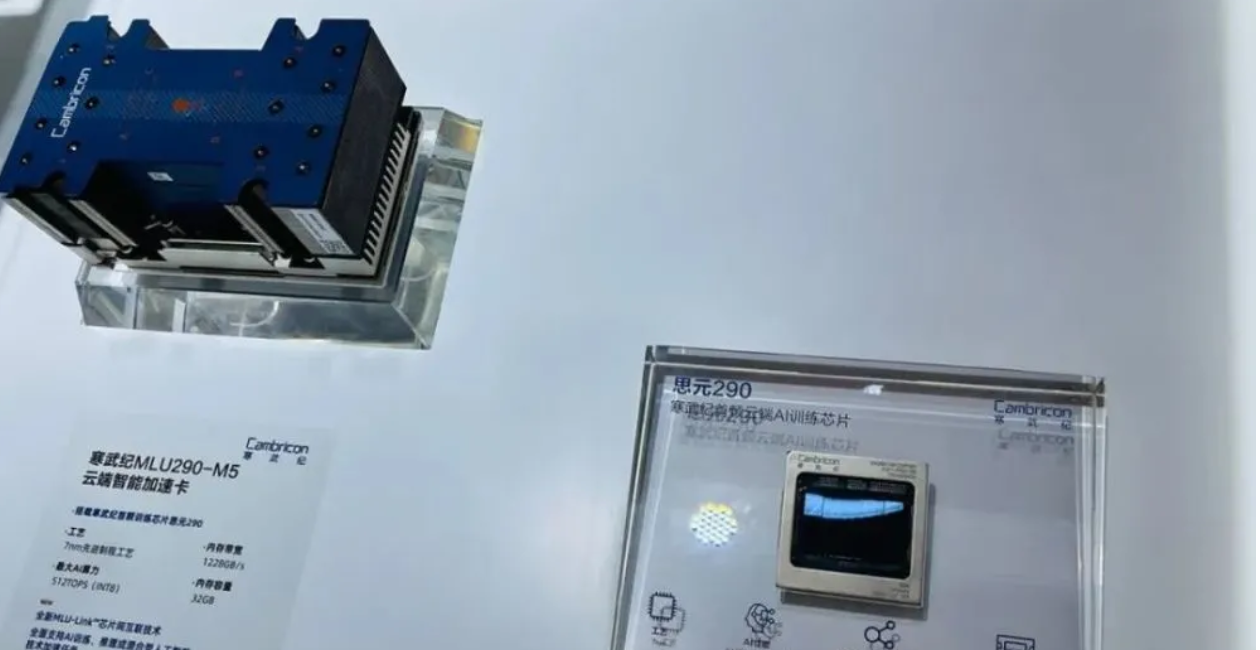

In fact, behind this global "lack of core" dilemma, the voice of domestic replacement is getting louder. Faced with the situation of "stuck neck", how to correctly develop domestic chip replacement has become a key topic in the industry.

Earlier, Yuan Chengyin, Secretary General of China Automotive Chip Industry Innovation Strategic Alliance, said in an interview that there are two ways to solve the chip shortage in the short term: one is to use our own resources to get as much as possible in the global chip distribution. More share; another is a determination to find alternatives.

Therefore, the realization of domestic substitution of semiconductors in multiple links for new energy vehicles in the future is still one of the key opportunities , not just slogans.

However, we can also see that the number of domestic chip design manufacturers has increased significantly in recent years. Everyone wants a piece of the pie, and the industry can easily fall into the dilemma of low-quality competition. Therefore, how to coordinate the healthy development of the industry will be the process. one of the challenges.