On March 17th, the High Technology Research and Development Center (Basic Research Management Center) of the Ministry of Science and Technology announced the top ten scientific advances in China in 2022. Among them, 10 major scientific advances, including the realization of high-efficiency fully perovskite stacked solar cells and modules, and the realization of direct electrolysis of seawater to produce hydrogen based on new principles, stood out from 30 candidate advances.

High efficiency and low cost perovskite batteries are a new hope in the photovoltaic field

There are many types of photovoltaic cells, which can easily make people unclear. According to the development history, it is mainly divided into three generations: the first generation of crystalline silicon batteries, the second generation of thin film batteries, and the third generation of new batteries.

The first category: silicon based solar cells, including monocrystalline silicon solar cells, polycrystalline silicon solar cells, and amorphous silicon solar cells. The first generation of solar cells has a high production cost, an average photoelectric conversion efficiency (PCE), a stable battery device, and a service life of about 20 years. Currently, they have been put into market application. In the path of crystalline silicon technology, there have been three stages of Perc-TOPcon-HJT.

The second category is multicomponent compound thin film solar cells, including gallium arsenide (GaAs), cadmium telluride (CdTe), copper indium gallium selenium (CIGS) solar cells, etc. These thin film solar cells have high conversion efficiency (PCE), good device stability, and simple preparation processes for battery devices. However, some of the material elements used in the batteries seriously pollute the environment and have little reserves on Earth, Hindering the commercialization and industrial mass production of this generation of solar cells.

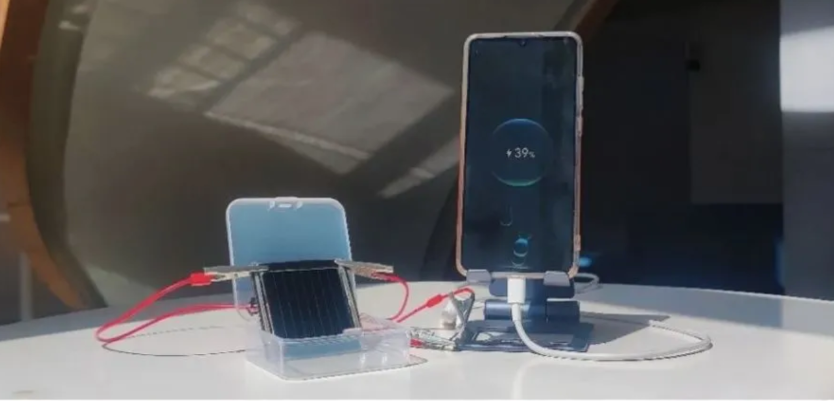

Category 3: New solar cells, including perovskite solar cells, dye sensitized solar cells, organic solar cells, quantum dot solar cells, etc. This type of solar cell has simple preparation process, large reserves of raw materials on the earth, and high photoelectric conversion efficiency.

Perovskite and crystalline silicon laminations achieve a 1+1>2 effect, with higher conversion efficiency and the fastest development speed. The perovskite solar cell can be used as a top cell to form a stacked solar cell with a silicon cell, namely a perovskite/crystalline silicon stacked solar cell. Perovskite silicon stacked batteries can be divided into two end stacks, three end stacks, and four end stacks. Currently, the laboratory efficiency record of single junction batteries has reached 25.7%, and the laboratory efficiency of double stack batteries has exceeded 31%; The theoretical efficiency of the double stack battery can reach 45%, far higher than the S-Q limit efficiency of the single junction battery of 33%.

From a cost perspective, compared to crystalline silicon batteries, perovskite solar cells have advantages in investment costs and production costs during their mature period. China Post Securities estimates that the component cost of a 5-10GW level mass production line is about 0.5-0.6 yuan/W, which is far below the limit production cost of crystalline silicon by 1 yuan/W.

The organization believes that perovskite batteries should have a wide range of downstream applications, which can be used to produce BIPV curtain walls and roofs, as well as roof photovoltaic. Zhongtai Securities stated that considering only the application of perovskite batteries in the BIPV field, the market space for perovskite battery equipment will reach 13.2 billion yuan in 2025.

| Layout of multiple companies and release of industrial investment plans

From the perspective of enterprise layout, currently the coating method is the main method for preparing calcium titanium ore layers. The companies using the coating method include GCL Optoelectronics, Dazheng Microelectronics, Xianna Optoelectronics, Renshuo Optoelectronics, etc. The main suppliers include Shanghai Dehu, Japan Dongli, etc. According to the news from Shanghai Dehu on November 27, 2022, among the core coating equipment supplies for the 500MW trial production line that has been built or is under construction in China, the supply of dehu slit coating equipment reaches 350MW, accounting for 70% of the market; Japan Toray supplies 150MW, accounting for 30% of the market.

With the promising potential of perovskite batteries, many listed companies have released investment plans for the perovskite battery industry. The industrialization process of perovskite solar cells has further accelerated. Among them, Baoxin Technology Co., Ltd. cooperates with relevant parties to establish a joint venture to carry out research and development, industrial technology research, and commercial solution promotion of perovskite heterojunction stacked battery technology, and applies corresponding technologies to the company's heterojunction battery projects.

Huangshi Group announced that its holding subsidiary Huangshi Nongguang Complementary (Guangxi) Technology Co., Ltd. and Shenzhen Heijing Optoelectronic Technology Co., Ltd. have signed an agreement to establish a cooperation mechanism to jointly promote the research and development, production, and product application of TOPCon/perovskite laminated battery product technology. Jingshan Light Machinery Co., Ltd. stated that the company has shipped perovskite equipment to head manufacturers, and is optimistic about the prospects of perovskite batteries. Han's Laser said that existing equipment can be applied to perovskite battery technology, but the proportion is not large. Aolian Electronics said that it has been developing perovskite batteries and has not yet produced them in mass production.

Three production lines of 100 MW perovskite photovoltaic modules have been built in China (GCL Optoelectronics, Fiber Optics, and Polar Photovoltaics). The institution believes that with the dual promotion of technology and capital, multiple GW level production lines are expected to be tendered in 2023 and will be implemented within 2-3 years.

| How to grasp the investment direction of perovskite batteries in 2023?

From the perspective of investment direction, it is recommended to focus on the incremental market and process changes brought by perovskite compared to crystalline silicon: the transformation of light absorbing materials from crystalline silicon to perovskite will eliminate the upstream silicon materials, silicon wafers, and the string welding process from midstream batteries to modules in the crystalline silicon industry chain, and the investment opportunities will focus on the remaining two major links of battery preparation and module packaging. Currently, the relevant production and manufacturing companies in these two major links are mainly non listed companies, while listed companies are active in the relevant production equipment and manufacturing auxiliary materials.

From an investment perspective, we are currently looking for opportunities along the two main lines of importance+certainty, and in the future, we will focus on changes in the demand for passivation layer and transport layer.